Ceramic Spray Coating: Improve Your Vehicle with State-of-the-Art Modern Technology

Ceramic Spray Coating: Improve Your Vehicle with State-of-the-Art Modern Technology

Blog Article

Achieving Specialist Results With Ceramic Spray Layer: Proven Techniques and Finest Practices Exposed

As experts in the field of automobile detailing and surface security are continuously looking for methods to elevate the top quality of their work, the application of ceramic spray coatings has become a game-changer. The allure of accomplishing a perfect, long-lasting completed with very little effort is obvious. However, the path to grasping this technique is paved with nuances and ins and outs that demand focus. Comprehending the crucial devices, surface area preparation strategies, precise application techniques, and upkeep methods are crucial components in the mission for professional-grade outcomes. By uncovering the tried and tested strategies and finest practices behind ceramic spray covering, a world of possibilities opens up for those seeking to elevate their craft and deliver impressive coatings.

Benefits of Ceramic Spray Finish

The advantages of using ceramic spray finish in various applications are well-documented and extensively recognized in the industrial and vehicle industries. Ceramic spray finishes offer phenomenal protection against ecological contaminants, UV rays, chemicals, and oxidation, supplying a sturdy shield for surface areas. One of the main advantages of ceramic spray covering is its premium durability compared to standard waxes or sealants. This longevity translates to set you back financial savings for businesses and customers alike, as the requirement for constant reapplications is dramatically minimized.

In addition, ceramic spray layers produce a hydrophobic surface that wards off water and protects against water spots, making cleansing and upkeep easier and much less taxing. The improved gloss and deepness of shade provided by ceramic layers can offer automobiles and industrial equipment a display room coating that lasts. Moreover, the scratch-resistant buildings of ceramic layers assist preserve the aesthetic appeal of surface areas gradually, adding to the general value and longevity of the layered items. To conclude, the benefits of ceramic spray finish make it a recommended choice for safeguarding and enhancing surface areas in a variety of applications.

Crucial Tools and Products

Having actually recognized the benefits of ceramic spray finish, it is necessary to lay out the vital tools and materials needed for its effective application in numerous industries. To achieve expert outcomes, the following products and devices are important:

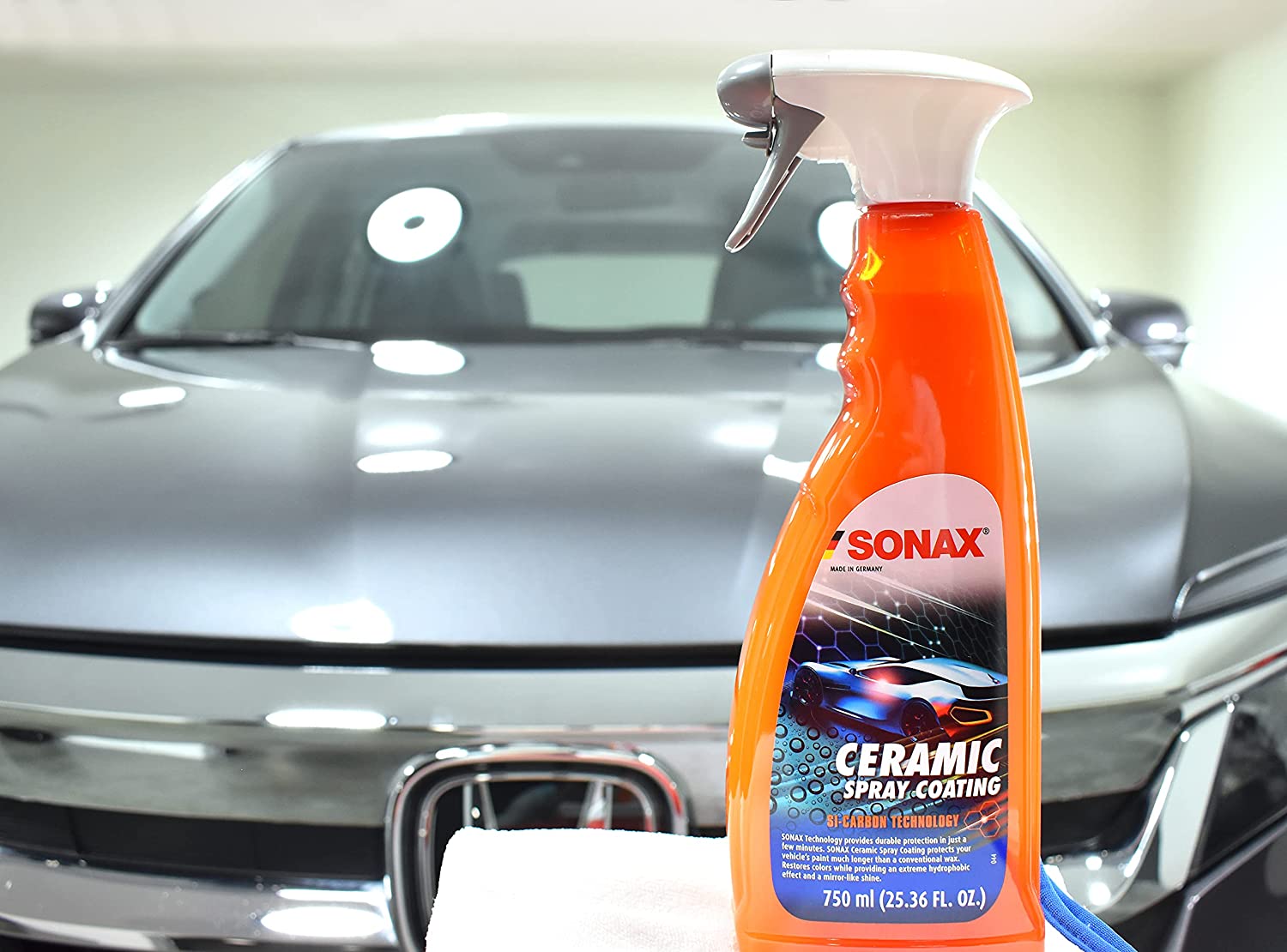

Ceramic Spray Finishing: The heart of the procedure, the ceramic spray coating itself supplies the safety layer that enhances toughness and aesthetics. - ceramic spray coating

Microfiber Towels: Utilized for wiping down the surface area before using the ceramic spray covering and for buffing off excess product after application.

Spray Bottles: Important for evenly distributing the ceramic layer onto the surface area.

Protective Gear: Gloves and masks to make certain safety and security throughout the application process.

Polishing Substance: For preparing the surface area by removing any flaws before using the ceramic finish.

Clay Bar: Helps in sanitizing the surface area by getting rid of embedded particles, making certain a smooth application.

Application Pads or Applicators: Utilized for uniformly spreading the ceramic spray finishing onto the surface area.

Correct Surface Area Preparation Methods

Efficient surface preparation is fundamental to guaranteeing the successful application of ceramic spray finishing in various markets. To attain ideal results with ceramic spray coating, correct surface area prep work techniques need to be used.

The very first action in surface preparation is complete cleansing. ceramic spray coating. Any address kind of dirt, wax, oil, or residue should be entirely eliminated from the surface to make certain proper attachment of the ceramic covering. This can be done utilizing a devoted surface or a gentle detergent cleaner

Next, the surface must be brightened to eliminate any blemishes such as swirl marks or scratches. This step not just improves the look of the surface area yet also ensures a smooth and even application of the ceramic coating.

Application Tips for Optimal Results

To guarantee extraordinary results with ceramic spray finish, precise interest to application techniques is critical following the precise surface area preparation treatments. When applying ceramic spray finish, it is vital to operate in a regulated setting devoid of straight sunlight or strong winds. Optimal application conditions normally include modest temperature levels and low humidity levels to assist in proper curing and bonding of the layer to the surface.

Previous to application, drink the ceramic spray layer container strongly to make certain the formula is well mixed. It is essential to work in tiny sections to ensure extensive application and stop the coating from drying out too soon.

After applying the ceramic spray finishing, allow adequate time for it to treat according to the maker's guidelines. When healed, utilize a high quality microfiber towel to delicately buff the surface to a high gloss coating. By following these application tips diligently, you can achieve ideal results and maximize the protective advantages of ceramic spray finish.

Upkeep and Long Life Techniques

Sustaining the long life and protective top qualities of ceramic spray finish calls for constant and methodical upkeep practices. To make sure sites the coating remains effective, regular cleaning with a pH-neutral automobile shampoo is necessary. This helps to eliminate dust, crud, and impurities that can break down the finishing over time. Furthermore, utilizing a mild microfiber wash glove and drying out the automobile with a soft, clean microfiber towel can protect against scrapes and swirl marks that could compromise the covering.

Periodic assessment of the coating is additionally essential for determining any areas that may call for touch-ups or reapplication. This can be done by carrying out an easy water beading test or aesthetically inspecting the surface for any kind of indications of wear. Dealing with any kind of concerns quickly can assist maintain the coating's safety buildings and extend its life-span.

In addition, preventing severe chemicals, abrasive cleansers, and automated vehicle washes can aid protect the stability of the ceramic spray covering. By adhering to these upkeep methods, specialists can ensure their ceramic-coated lorries maintain a high degree of security and visual allure for a prolonged period.

Final Thought

Finally, achieving specialist outcomes with ceramic spray finish calls for careful consideration of vital devices and products, appropriate surface prep work strategies, and application pointers for optimum results. By following tested techniques and best techniques, maintenance and long life of the finish can be taken full advantage of. It is vital to stick to these standards in order to achieve the preferred expert results and ensure the performance of the ceramic spray coating.

As professionals in the field of automobile describing and surface security are regularly looking for means to raise the high quality of their work, the application of ceramic spray coatings has arised as link a game-changer.In addition, ceramic spray coverings develop a hydrophobic surface that wards off water and avoids water places, making cleaning and upkeep much easier and less lengthy. In verdict, the advantages of ceramic spray coating make it a recommended choice for shielding and improving surface areas in a variety of applications.

To make certain phenomenal outcomes with ceramic spray layer, careful interest to application techniques is vital adhering to the meticulous surface prep work treatments.In final thought, attaining specialist outcomes with ceramic spray coating needs mindful factor to consider of crucial tools and products, appropriate surface prep work strategies, and application ideas for ideal results.

Report this page